Column crack repair is one of the basic steps taken in restoration operations with the aim of returning the building to its original state again. In some cases, it may be necessary to take additional steps to avoid the appearance of cracks again.

The steps to treat these cracks depend on the structural study of the building and determining what are the causes of the appearance of column cracks, which contributes to identifying appropriate solutions and remedial procedures necessary to maintain the building’s lifespan.

In this article, we will discuss the types of cracks in concrete, the most dangerous types of cracks, and how to treat problems with concrete columns. Follow along with us.

Types of cracks in concrete

Before Column crack repair, you must first know the types of concrete cracks, which are one of the common problems that affect the durability of concrete structures in buildings or sidewalks. These cracks occur as a result of a variety of reasons, including shrinkage, excessive bearing, and environmental influences. In that paragraph, we will convey What are the types of cracks in concrete:

- Plastic Settlement

- This happens when water moves from the concrete to the soil and this causes fine particles to collect at the bottom. Plastic deposition is a process in which fine plastic particles are added to the concrete mixture with the aim of improving the mechanical properties and increasing its resistance to cracks. It also contributes to reducing cracks resulting from thermal expansion and load. Excess.

- Plastic Shrinkage

- Plastic shrinkage occurs when concrete begins to lose water rapidly during the initial drying stage, causing some surface cracks to appear. This phenomenon occurs after the concrete has been poured and dried, as the loss of water present in the mixture during hardening leads to shrinkage of the concrete, which leads to cracks in the surface within the structure. Concrete especially in hot weather, so column cracks must be treated when they are noticed early.

- Early thermal contraction

- Premature thermal shrinkage is a type of crack that occurs due to the shrinkage of concrete as a result of a decrease in temperature in the early stages of pouring. This shrinkage occurs when the concrete cools quickly and shrinks in size unevenly, leading to the appearance of cracks on the surface or inside the structure for column crack repair. Concrete materials can be used to inhibit this shrinkage.

- Long-term drying shrinkage

- This type of shrinkage occurs due to the long-term loss of water from concrete, which leads to the appearance of cracks.

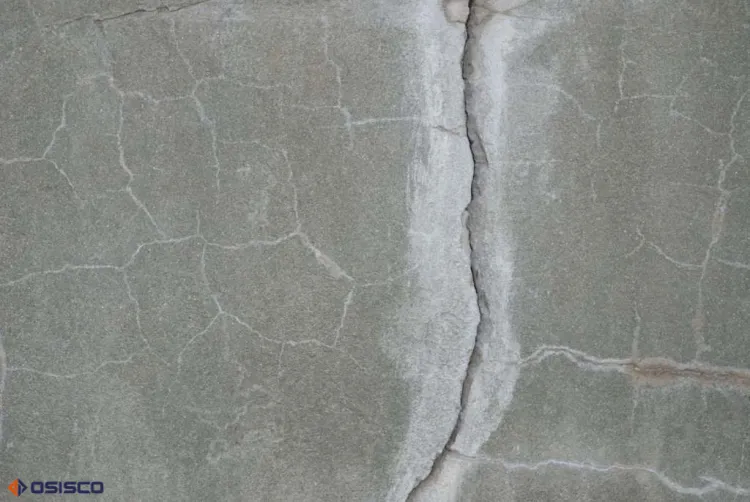

- Crazing mosaic cracks

- It occurs due to rapid drying, which leads to cracks on the concrete surface.

- Corrosion of Reinforcement

- This corrosion occurs when the iron inside the concrete is exposed to moisture and salts, which leads to a loss of concrete durability.

- Alkali-aggregate reaction

- It occurs when alkaline substances react with mineral substances in the aggregate, causing cracks and damage to the concrete.

- Leave diastolic Expansion Crack

- It occurs due to the expansion of materials inside the concrete, which leads to cracks in the structure, which requires treatment of cracks in concrete columns.

These terms refer to different types of cracks that may affect concrete, each type requiring specific preventive measures and treatments to ensure they are repaired properly and maintain the long-term durability of the concrete structure.

Epoxy Injection Foundation Crack Repair Cost

The cost of epoxy injection for foundation crack repair varies depending on several factors, such as the severity and length of the cracks, the location of the property, and the expertise of the contractor. Typically, epoxy injection is considered an effective and long-lasting solution for structural cracks in foundations, as it restores strength and prevents further damage. On average, homeowners might expect to pay between 0.00 and 0.00 per crack, but this can increase for larger or more complex repairs. Investing in professional epoxy injection services ensures the safety and stability of your property in the long run.

Read more about: epoxy injection

Concrete column processing

Column cracks are treated with a concrete shirt, which is a layer of longitudinal steel reinforcement and collars. It is used to increase the resistance of the column against bending and to strengthen the columns in cases where the damage is severe or when the column is unable to bear the lateral aspects sufficiently.

The concrete shirt can be applied completely around the column or on one side only. The success of treating column cracks depends on the extent of the shirt’s connection and cohesion to the original column.

If the thickness of the shirt is small, there will be no increase in stiffness. Also, the concrete shirt leads to an increase in the dimensions of the column, which may cause architectural challenges and increase the weight of the building. In some cases, the adhesion between the new and old concrete is the main factor that guarantees the integrated performance between them, thanks to the roughness of the old surface. .

If the concrete shirt is implemented on only one part of the column, then the old and new collars must be welded together to ensure Their cohesion In the need to increase shear resistance without affecting bending resistance, the shirt can be disconnected from the roof and sills.

Column crack repair after pouring

OSISCO engineers work to treat cracks in columns and ceilings after casting by examining the cracks in concrete columns to determine the appropriate treatment for them. Treatment methods include the following:

- Treating rust cracks and multiple cracks

- Concrete columns are strengthened using a concrete shirt to treat rust cracks and cracks. The number and diameters of the reinforcing steel bars are determined according to the condition of the column and the required shirt dimensions.

- Restoration of columns to address minor rust cracks

- This method is used in cases where the effect of rust on the reinforcing steel is minor, as the rust does not lead to the separation of the concrete cover, and thus there is no need to increase the column dimensions.

- Treating horizontal cracks

- Widen the cracks from the upper side to a width of no less than 5 mm.

- Fill horizontal cracks using epoxy mortar such as Kima Poxy 103 until it reaches the opposite surface of the concrete.

- Cleaning cracks by removing dismantled concrete parts after they dry.

- Filling the cracks with low-viscosity epoxy materials to ensure they are completely covered.

Cracks in concrete columns

Cracks in concrete columns are a common phenomenon that occurs as a result of several factors, including excessive stress, thermal shrinkage, exposure to a harsh environment, or the use of materials that do not meet specifications, which require rapid crack between wall and column. These cracks can be superficial or extend deep into the concrete and vary in size and effect on the surface. The strength of the structure and the most important types of column cracks are the following:

- Oblique diagonal incisions

- Diagonal cracks appear in concrete columns on the entire face of the column, at any location along its length and height. The main reason for these cracks is the insufficient bearing capacity of the columns, where the column section is insufficient and the reinforcing steel is inappropriate. In addition, horizontal forces from earthquakes and wind, which have not been carefully considered, can cause these cracks to appear.

- Overload cracks

- Overload cracks in a reinforced concrete column are short, parallel vertical cracks of irregular width.

- Columns with insufficient reinforcement and poor quality concrete are susceptible to the appearance of these types of cracks.

- Overload cracks appear in concrete columns due to reaching the maximum load capacity.

- Corrosion cracks and rust

- Vertical column cracks that appear in concrete columns are treated along the line of the reinforcing bars. This type of crack is usually uniform in width, as it widens with the passage of time and increasing the age of the column.

- Exposure to moisture, insufficient concrete cover, and poor bonding between iron bars and concrete are the main reasons that lead to corrosion cracks and rust in concrete columns.

What is Column crack repair?

- The cracks are cleaned using a putty knife, as the width of these cracks ranges between 2 to 3 mm.

- The crack treatment paste is prepared and applied to the crack after cleaning it well.

- Leave the paste for several hours until it dries completely, then polish the damaged area until it becomes level with the surface. Repeat this process several times until the desired result is achieved.

- The walls are painted again using finishing paints, making sure to choose high-quality paints to ensure the protection of the walls and prevent any future damage.

Cause of concrete cracks

Weather and environmental factors such as heat and humidity greatly affect concrete, and when sudden changes occur in these factors, this can lead to expansion and contraction of concrete, causing cracks.

At high temperatures, concrete expands while it contracts when temperatures drop. These changes create internal pressure that leads to cracks. Humidity also plays an important role, as dryness leads to concrete shrinkage and cracks, which requires immediate crack between wall and column so that the building is not damaged.

While excess moisture may cause it to expand and form cracks, proper management of these factors is essential to maintain the integrity of buildings.

In addition, the use of components and products that are not suitable for concrete can lead to weakness of the concrete and the appearance of cracks, so it is necessary to ensure the quality of cement, sand, gravel and water to ensure the durability of the building.

OSISCO is a pioneer in providing these necessary materials for construction, strengthening, and treating column cracks. To obtain more information, you can contact OSISCO’s experts and engineers.

Methods of restoring concrete columns

- Use of formwork: When implementing a concrete shirt, it is preferable to use formwork with self-leveling concrete. If the thickness of the concrete cover is small, the use of concrete brushes is considered the best option in treating column cracks.

- Application of the shirt: After installing and tying the iron rods around the column, concrete is poured and the formwork is tightened in stages.

- Pouring concrete: The process of pouring concrete between the column and the roof is considered one of the most important stages.

- Ensure adhesion: To ensure good adhesion between new and old concrete, special adhesives must be used.

- Concrete Shrinkage: If the concrete cover surrounds the column, shrinkage of the new concrete will cause friction between the old concrete And concrete The new ones eliminate the need to plant maraghi.

If the strength of the new concrete is higher than the old one, the increased cross-section of the column can be taken into account when analyzing the flexural strength of the reinforced column and the flexural capacity of the finished column can be considered to be up to 90% of the calculated values.

How to strengthen concrete columns

If you want to strengthen concrete columns to suit the increased load of the column, whether due to an increase in the number of floors or due to a design error or the compressive resistance of the concrete column, or the proportion and quality of the reinforcement steel is less than the standards specified in the standard specifications.

Or if there is a slope in the columns more than what is allowed in the standard specifications or there is a collapse in the foundations, here are the best ways to strengthen and treat column cracks:

First, cracks in columns in the previously mentioned cases are strengthened and treated by making a concrete shirt. The dimensions of the concrete shirt, in addition to the diameters and number of reinforcing steel bars, depend on the requirements that necessitated this procedure, according to the following steps:

- The layers of whiteness are removed and the concrete surface is cleaned well.

- All surfaces are sanded in a way that ensures that the integrity of the column is not affected.

- Asheer is planted to connect the new canes of the shirt in both directions at distances ranging from 25 to 50 cm. The pillars are installed by making holes in the surface of the column with a diameter 2 mm greater than the diameter of the pillars.

- Clean the holes well with compressed air and paint them from the inside with epoxy (Kemapoxy 150), then fill them with Kemapoxy 165 mortar and plant the sign, making sure that the sign is long enough to connect them to the new sides of the shirt with wire ties.

- These signs are planted by making holes in reinforced concrete foundations or in beams, depending on the situation. The diameter of the holes is larger than the diameter of the sign by 2:4 mm, and their depth is about 5 to 7 times the diameter of the sign.

- The holes are cleaned using compressed air, then painted with Kemapoxy 150, then filled with Kemapoxy 165 mortar, and the sign is installed.

- The vertical iron is installed first, then the columns are installed according to the design of the column shirt.

- The surface of the column is painted with Kimapoxy 104 to bond the new concrete to the old. Care must be taken to pour the shirt concrete before the paint dries.

- The shirt is poured from non-shrinking concrete consisting of fine aggregate (pheno), sand and cement at a ratio of no less than 3^400 kg/m and anti-shrinkage additives such as Adekrete BVS or Adekrete BVF at a ratio of no less than 6kg/m^3.

- The shirt concrete is poured either using a concrete cannon (ShotCrete) or through regular formwork, by making holes in the formwork and in the roof slab, with the shirt poured in stages to ensure effective curing.

read more about column crack repair from this link