concrete crack injection companies are considered the cornerstone in the field of maintenance and strengthening of concrete structures, as this technology contributes to treating cracks and damage that may threaten the safety of buildings and infrastructure.

Among the leading companies in this field, OSISCO stands out thanks to its extensive experience and innovation in providing advanced and effective solutions.

OSISCO is distinguished by its use of the latest technologies and high-quality materials to ensure that concrete is permanently repaired and enhances its resistance to various environmental factors.

Concrete injection materials

Concrete crack repair injection materials are among the most important means used to restore the strength and durability of damaged concrete structures, as they play a pivotal role in treating cracks and fissures to ensure continuity of structural integrity. The most prominent of these materials are:

- Epoxy: It is used by concrete crack injection companies to grout large cracks and structures that need to restore their load bearing thanks to its high adhesion and durability, which ensures a permanent repair.

- Polyurethane: An ideal choice for grouting small to medium cracks, as it is extremely flexible and able to expand to fill voids and prevent water leakage, making it ideal for insulation applications.

- AFor modified cement: It is used to repair large cracks that require an economical and effective material that enhances strength and durability. It is characterized by its ease of use and low cost.

- Acrylic generation: It is an innovative material used for injecting microscopic cracks. It is characterized by its high flexibility and water resistance, making it ideal for isolating microcracks in concrete structures.

In this field, OSISCO stands out as one of the leading concrete injection companies in providing concrete crack injection services using these advanced materials. It is distinguished by its extensive experience and specialized team that uses the latest technologies to ensure accurate and sustainable repair of concrete cracks.

The company also relies on high-quality materials such as epoxy, polyurethane, modified cement, and acrylic gel to provide comprehensive solutions that suit all types of cracks and customer requirements, making it the ideal choice to ensure the efficiency and durability of concrete installations.

You can read more about concrete injection from this link

Soil injection under foundations

Subsidence of foundations is considered one of the most prominent problems facing buildings, and it results from multiple reasons, including defects in the implementation of the facility, errors in the engineering design, or changes surrounding the building that lead to cracks or tilts in the structure.

To deal with this problem, OSISCO, the best certified leak inspection company, provides advanced solutions to address foundation subsidence using soil injection technology under the foundations.

This technique is one of the most effective ways to repair damage without having to demolish the building, ensuring that its stability is restored with high efficiency.

The soil injection process involves pumping special materials such as solid cement or polyurethane materials into the damaged soil at different depths.

This procedure aims to improve the properties of the soil and strengthen it, which stops the subsidence process and prevents further damage. The reasons leading to foundation subsidence are varied, including the nature of the surrounding soil, which may be sandy, rocky, or clay, in addition to weak reinforcement or low quality of concrete used in construction.

Before starting the injection process, careful laboratory tests of the soil are conducted and its properties are studied to determine the most appropriate method of injection through concrete injection companies.

OSISCO Concrete Technology Company relies on the latest technologies and equipment to provide customized solutions that suit the nature of the soil and the size of the problem, taking care to achieve the best results and ensure the stability of the facilities in the long term. This service is not limited to treating subsidence only, but also enhances the life of the facilities and their ability to resist conditions. different environmental.

Soil injection with concrete

Collapse of buildings is a common problem that occurs due to several factors, the most important of which is the quality of the soil, which may be sandy, rocky, or clay. Collapse may also result from less common causes such as weak reinforcement or poor quality of concrete (which consists of a mixture of cement, sand, gravel, and water).

To address this problem, concrete crack injection companies resort to soil injection technology under foundations, which aims to improve and reinforce concrete to increase its ability to bear the loads placed on it or that may be imposed in the future. Among the methods of soil injection are:

| Cement injection | Soil injection with chemicals |

| Cement injection is one of the techniques used to fill voids between soil particles. This method is based on a special design through which a cement mixture is pumped under pressure through one or multiple pipes. The size of the injected material particles is chosen to fit the spaces between the soil so that it can pass easily.This technique is used to improve the strength of the soil or reduce its permeability. It is also applied to strengthen the soil under foundations and support the sides of excavations. Injection is done through concrete injection and soil injection companies, usually by drilling holes in the soil and then pumping the mixture under pressure to ensure the stability of the mixture. The cement is mixed with water with additives to improve its properties, and the mixture is adjusted periodically during work to achieve the desired results, whether to reduce permeability or increase strength. | This method is used in sandy or loose soil, and aims to transform porous soil into cohesive rock masses. Ports are drilled within the damaged layers and metal tubes are installed to inject the chemical mixture. These materials have a low viscosity to ensure their flow and homogeneity within the soil, which turns them into cohesive rock blocks from the lowest point to the highest level.Common applications of this method include: enhancing the durability of the soil on the sides of excavations before starting excavation work, which contributes to obtaining strong and durable walls, preventing water leakage from the lower layers under the backfill soil under buildings, especially in areas that contain waste and debris remains such as wood and blocks. . |

Soil injection with cement

Urban expansion and population growth in cities have led to the need to build large facilities that meet human needs. The soil may sometimes have difficulty bearing heavy loads, or builders may be forced to erect the facilities partially or completely below the groundwater level.

In this topic, we will discuss the first solution related to soil injection, which is one of the effective economic solutions to reduce the cost of replacing soil on sites, as well as reducing the risk of collapse of existing buildings as a result of irregular subsidence.

This subsidence occurs due to many factors, such as the rise of groundwater, soil composition, pH, and salt content, in addition to the loads applied to the soil.

The solution is to inject the soil under the foundations using specific chemicals, chosen according to the project characteristics, which enhances the stability of the foundations and resists soil changes that cause collapses. This procedure can contribute to increasing the life span of the facility.

The soil injection process is also used to address soil subsidence beneath structures, strengthen soil in coastal areas, and fill caverns under foundations.

The process involves drilling holes of specific depth and diameter, then injecting cement mortar under pressure with the addition of chemicals to improve the structural strength of the concrete, achieving a void-free and strong area.

OSISCO, the best company for supporting foundations with piles, provides soil injection service with the highest level of efficiency and experience in Egypt, which ensures the stability of facilities and protects them from the risks of subsidence and soil changes.

Treatment of cracks in concrete

Treating cracks is an essential step in restoration to return the building to its original condition, and additional measures may be required to prevent their recurrence based on a structural study to determine the appropriate causes.

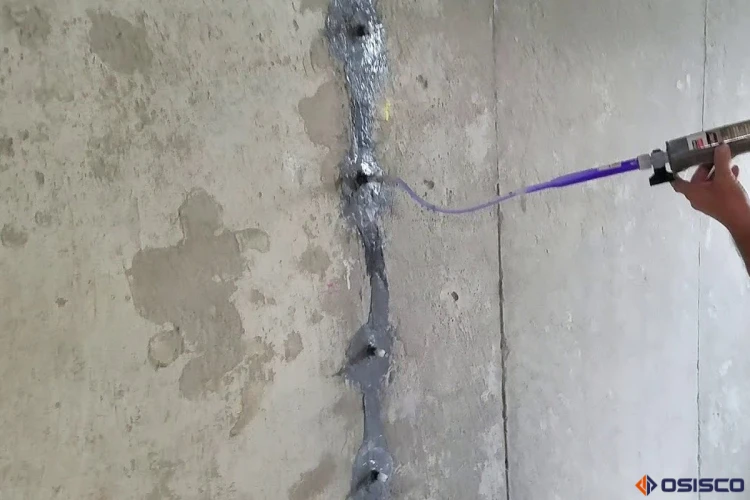

Impermeable hairline cracks are treated by concrete crack injection companies using low-viscosity epoxy materials that seep into the cracks after cleaning and drying the surface. As for small horizontal cracks, they are widened and then filled with epoxy or cement mortar after cleaning them well.

As for deep cracks, they are treated by injection under air pressure using epoxy mortar, with metal pipes installed to ensure effective distribution of materials.

with regards to shine When widening, the crack is cleaned and then filled using materials such as epoxy or cement mortar, while treating the surfaces with rust-preventing materials in some special cases.

If you are looking for effective and high-quality solutions in the field of crack treatment and restoration, contact OSISCO, the best concrete injection company. Our long experience and introduction of the latest technologies guarantee you outstanding results. Contact us now to obtain integrated restoration services for your construction needs.

Read more about: Column Crack Repair

Concrete injection companies in Egypt

OSISCO is one of the leading companies in the field of concrete crack injection and insulation solutions in Egypt. Thanks to its extensive experience in treating cracks and restoring buildings, OSISCO offers the latest technologies and effective materials to ensure the sustainability of concrete and protect it from environmental and construction impacts.

Through our use of the best insulating materials and advanced injection methods, the company provides innovative solutions that maintain infrastructure quality and prevent facility deterioration. OSISCO’s commitment to quality and innovation makes it the ideal choice for construction projects in Egypt.

Soil injection prices

Soil injection services provided by companies in Egypt vary, but at OSISCO, the best concrete injection company, we work hard to provide distinguished services at competitive prices. There are several factors that affect determining the cost of soil injection, the most important of which are:

- Providing customized solutions to address various soil problems.

- Determine the optimal way to reach the desired location for subsoil injection.

- The time required to successfully complete the services.

- The type of materials used to strengthen the soil and increase its hardness.

- Modern methods and innovative technologies adopted at work.

- Tools and materials used in the injection process.

- The planned implementation strategy for each project.

All of these factors contribute to determining the final cost of the soil injection service that we provide. You can contact the best concrete crack injection companies via the following number: +201000927271 to obtain more details about our prices, and to benefit from our integrated services. We are keen to provide high-quality services using the latest equipment and technologies to ensure satisfactory and lasting results.

We seek to provide distinguished services to all our customers throughout the Arab Republic of Egypt at reasonable prices that suit all categories. Do not hesitate to contact us to take advantage of the best offers and services available.

Read more about: soil injection