Polyurethane foam is considered one of the most prominent modern insulation systems, as it has proven its effectiveness. This material is sprayed onto the surface to be insulated to provide effective protection, and it differs significantly from traditional insulation methods in terms of speed and ease of implementation.

Experts and technicians agree that its efficiency surpasses other materials used for the same purpose. This means customers can rely on polyurethane foam without needing to use multiple insulation materials or methods inside their homes or other buildings. This material boasts numerous properties and advantages that have made it a preferred choice for many. To ensure optimal results, it is recommended to obtain insulation materials from OSISCO, which provides high-quality polyurethane foam and offers 24/7 customer service for any inquiries

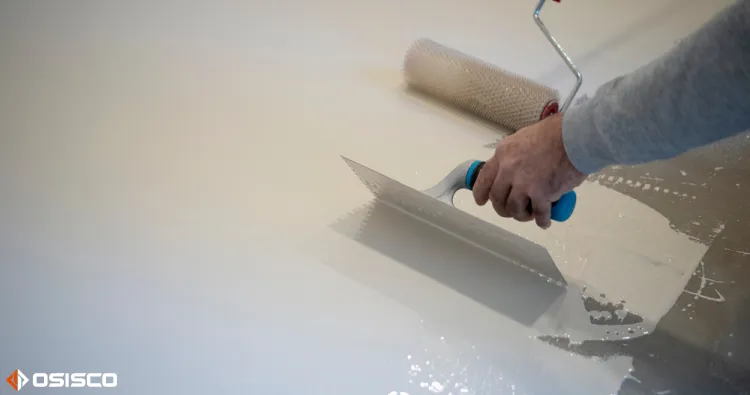

Polyurethane flooring

Polyurethane foam is one of the insulation methods that was discovered recently, and this material has performed well when used. This material is known for being the least electrically conductive material, in addition to being the lowest in terms of heat conduction. Customers’ use of injecting polyurethane foam makes them able to do without Unlike all other insulation materials and methods, no material will provide the same level and efficiency of insulation service provided by polyurethane foam. The role of this foam insulation is not limited to thermal insulation only or water insulation only, but rather It is suitable for both types, as it is a material that provides a complete insulation service against water as well as heat, and unlike the insulation methods witnessed in the market, this type makes the surface cohesive and consists of only one panel, free of joints that may cause a defect in the efficiency of the quality of heat insulation, and the material has This has a set of characteristics, including the following:

- Able to outperform all other types and materials that are used to obtain excellent insulation results with a long shelf life.

- A material that has a great ability to resist all different conditions and varying weather factors.

- It can be used in most industrial sectors.

- It is used in a very easy way, as it is distributed by spray.

- Able to withstand the pressures and loads of all industrial sectors in which the nature of work differs from the usual.

- injecting polyurethane foam insulation is easy to spray and is suitable for insulating all shapes that are classified as irregular.

- Corners and crannies are among the places that are difficult to insulate with any traditional material, but from now on you do not have to worry about those places, as they will be sprayed with polyurethane foam.

Uses of polyurethane

injecting polyurethane foam is a plastic material, but it is light in addition to being foam. This material is characterized by a different set of properties that qualify it to be the best insulation material ever. Polyurethane for flooring is of great importance and has become everyone’s demand, and the uses of this insulating material are multiple, unlike other materials. Its use is limited to a limited scope, and the most prominent uses that have been proven effective are the following:

- Capable of thermal insulation with an unprecedented degree of efficiency.

- It can provide sound insulation services.

- It is used in the manufacture of many pieces of furniture.

- A number of furnishings are manufactured by it.

- Suitable material for shoe making.

- Packages are made from this material.

- Insulating pipes for petroleum storage.

- Decoration industries.

- It is used in the manufacture of all containers used for refrigeration.

Read also about: Epoxy Paint Price

Polyurethane injection for waterproofing

Polyurethane is known as a resinous material with very low viscosity levels. It is known for being the most flexible and completely free of various types of solvents. When this material comes into contact with water, it begins to form and change to become a material with a porous but closed structure, and this contributes to making it a water-resistant material. It is suitable for waterproofing, and specific steps are applied in order for the correct insulation to be achieved using this material. The steps are characterized as follows:

- Specialized engineers, experienced technicians and skilled workers inspect the surface first.

- The necessary inspections, examinations, and inspections are initiated immediately in order to obtain all the information and determine the type of surface and the problems that arise on it, in order to determine the two work steps.

- Identify existing problems accurately.

- Develop a set of radical solutions through which the problem will be eliminated.

- The client will be informed of the actions that will be taken.

- The appropriate working method will be determined by specialists, in addition to preparing the polyurethane foam used in insulation.

- Initiate immediate preparation of tools, equipment, etc. in order for the task to begin.

- Solve the problems of cracks, fissures, and cracks, in addition to water leakage, if they exist.

- Start laying the layers of insulating material that were chosen according to the surface characteristics continuously, successively, and cohesively on top of each other.

- Begin deep cleaning work immediately after completion of insulation services.

- Testing the material that was placed to ensure the success rate of the insulation process.

What are the advantages of liquid polyurethane?

Liquid polyurethane foam is considered one of the best modern insulation materials, thanks to its unique properties that combine high efficiency and ease of application. It is widely used for insulating roofs, tanks, bathrooms, and other structures, and is characterized by the following:

- It is lightweight and does not add any extra load to the building structure.

- It forms a cohesive insulation layer without gaps, which effectively prevents water leakage.

- It has great flexibility, giving it the ability to expand and contract with changes in temperature.

- It provides excellent insulation against external factors such as heat, cold, and noise.

- It has a long lifespan and maintains its efficiency for years without the need for continuous maintenance.

- It can be sprayed onto complex surfaces and delicate corners with complete ease.

- High resistance to corrosion and friction, giving it great long-term durability.

- Thanks to its high thermal insulation capacity, it contributes to reducing energy consumption.

- It prevents the growth of fungi and bacteria thanks to its resistance to moisture.

Insulating surfaces with polyurethane

Insulating with polyurethane gives you effective and desirable results, especially if the material was obtained from a reliable source such as osisco. We are able to provide the quantities you want with an unprecedented degree of purity, in addition to that we guarantee you the quality of the results, and this material is classified in addition to polyurethane. Urethane foam is considered the best insulation material, as it is suitable for use on all types of surfaces, whether the surface is concrete or built, or even made of wood or metal panels, and the reason is due to its strong adhesion, and the use of these materials has become widespread. Recently in all parts of the world, it has become one of the basic materials that provides a competitive service to everyone. It is preferable to use this insulating material to insulate upper surfaces, because it provides many benefits, including the following:

- Maintaining coolness levels throughout the summer.

- Loft insulation services with this material prevent any heat loss.

- It makes the house full of warmth throughout the bitterly cold winter season.

- injecting polyurethane foam prevents noise from penetrating your home, meaning you won’t suffer anymore from noise pollution.

- Noticeable savings in total bills paid.

- Reducing carbon dioxide levels in the atmosphere.

- Preserving nature and the environment surrounding the house.

- It reduces the level of mingling of the home with everything that is happening in the world.

- polyurethane material insulation increases the financial value of your home by a very high percentage.

Insulation with foam or polyurethane

Insulation is one of the most important measures, and we must direct our attention to it in order to limit the occurrence of problems that result from its lack, as insulating various surfaces results in the highest percentage of protection ever, and insulation has an effective role in reducing the impact of both the negative impact resulting from rain and floods. And very high or very low temperatures, and the materials provided by osisco that are used in the insulation process have a set of properties, the most important of which is that they have very high thermal properties. We only provide you with insulation materials with high mechanical properties that will be able to withstand periods of time. Long It is resistant to loads, and despite the presence of several types of insulating materials, injecting polyurethane foam is the distinctive one among them and is in high demand. Among the most prominent of these features are the following:

- Polyurethane foam is a lightweight material.

- It has the ability to expand as well as contract.

- It is easy to manufacture in more than one shape and in many different sizes.

- It has extremely great resistance ability against water and leakage.

- Able to resist moisture.

- Suitable for thermal insulation situations.

- It is performed in the least possible time unlike various insulating materials.

- Customers are allowed to use surfaces after insulating them for a short period, not a long period.

- It is possible to control the thickness of the insulation layer and it is determined based on the specific needs of the target location.

- It is not affected by fungi at all, and it is also not affected by insects.

- You will not suffer from unpleasant odors that cause inconvenience with polyurethane foam, which is known to be the best insulating material.

- injecting polyurethane foam does not contain any organic materials.

- Polyurethane for flooring gives a very perfect system for all metal surfaces.

- It does not cause harm to the individual or even to the environment.

Steps to implement the process of insulating surfaces with injecting polyurethane foam

There are very important procedures that must be taken into consideration when carrying out the process of insulating the surface with injecting polyurethane foam. This process is not a random process, but rather a process that requires precision to ensure obtaining a result with desirable efficiency and performing the role assigned to it with extreme efficiency. Also, dealing with the surface that In the beginning, isolation has already been done differently, and this process takes place in two stages, and here are the details:

The first stage: the stage of preparing and preparing the surface to be insulated

- It is necessary to begin the surface sanding procedure if there are parts that have been affected by rust, using the brush designated for this matter.

- You can resort to electric sanders if there is a large area covered by rust on the surface.

- The surface must be cleaned deeply in order to get rid of any dust or even oils and greasy materials, using hand tools or even a mechanical device.

- The final stage is the isolation stage:

- The steps of this stage begin with adjusting the spray machine and setting the appropriate temperature in addition to the pressure as well.

- Start heating the machine to a temperature between 40 to 50 degrees Celsius.

- It is the turn to prepare all the spray tools that will be used to begin the insulation.

- In the next step, injecting polyurethane foam will be sprayed, but with an average thickness of 3 cm.

- The spraying process takes place in three stages, and care must be taken to close sufficient areas where there is any gap or void.

- It is necessary to cover the surface so that it is not damaged by ultraviolet rays from the sun, which may cause problems.

Polyurethane price in Egypt

The price of polyurethane foam in Egypt is determined based on a number of key factors, most notably:

- The thickness of the insulation layer required depends on the thickness; the greater the thickness, the higher the consumption and therefore the higher the cost.

- The area of the roof, where the price varies according to the total area to be insulated.

- The type of polyurethane used (spray foam – injection – curing) has a different price for each type.

- The quality of the raw material and its conformity to standard specifications.

- The condition of the surface before insulation and the extent of the need for additional preparation or treatment work.

- The height of the building, the nature of the site, and whether there are difficulties in access or implementation.

Read more about: Soil injection