When it comes to safety in residential, commercial and industrial facilities, choosing slip-resistant flooring is one of the essential factors that ensure a safe environment for users, whether in hospitals, factories, restaurants or even outdoor spaces.

Non-slip flooring significantly reduces the risk of accidents and improves the efficiency and safety of movement. In this context, OSSISCO offers advanced solutions in the field of Slip resistant floor based on the latest technologies and high-quality materials that ensure durability, outstanding performance and elegant design that suits various needs. Follow this article with us for more details about slip resistant floor tiles.

Sanitary floors

Sanitary flooring plays an essential role in maintaining a clean and safe environment, especially in facilities that require strict health standards such as hospitals, food factories, and laboratories.

These floors have antibacterial properties, are easy to clean, and are resistant to moisture and chemicals, which prevents the accumulation of germs and ensures a high level of sterilization.

It is also available in different types, such as slip resistant epoxy flooring, polyurethane, and vinyl flooring, which is characterized by its non-porous surface, which reduces the chances of the spread of contaminants. Choosing hygienic flooring not only enhances hygiene, but also contributes to improving indoor air quality and safety of individuals in various environments.

Chemical resistant flooring

Thanks to these advanced solutions, OSSISCO ensures the provision of industrial flooring that combines superior performance and durability, making it the ideal choice for different industrial sectors.

OSSISCO provides a variety of chemical-resistant floors specifically designed to meet the needs of food and beverage factories, as they are distinguished by their high quality and ability to withstand harsh conditions. The most prominent of these types are:

- EOC epoxy flooring: It is resistant to chemicals and heat and provides a smooth surface that is easy to clean. In addition, its high flexibility reduces the possibility of it breaking under heavy loads.

- Polyurethane flooring: Ideal for facilities that face temperature changes and high levels of humidity, as it is characterized by its strong resistance to acids and alkalis, as well as being anti-slip, which enhances safety in working environments.

- Rubber flooring: used in areas that may be exposed to mechanical shock, as it provides additional protection and shock absorption, which reduces stress on workers and enhances their comfort while working.

Thanks to these advanced solutions, OSSISCO ensures the provision of industrial flooring that combines superior performance and durability, making it the ideal choice for different industrial sectors.

Read more: Concrete Floors

Flooring for pharmaceutical factories

Floors are an essential element within medical and industrial facilities, especially in hospitals and pharmaceutical factories, as these environments require special specifications to ensure the highest levels of safety and cleanliness.

In this context, epoxy flooring is an ideal solution for these facilities due to its unique properties that meet the requirements of sensitive environments.

The importance of flooring in hospitals and pharmaceutical factories is not limited to the aesthetic aspect only, but rather plays a vital role in ensuring a safe and healthy environment for patients and workers.

Therefore, it is necessary for flooring to meet certain requirements to ensure that it can withstand harsh conditions and maintain its quality in the long term. The most important of these specifications are the following:

- Resistance to bacteria and fungi: Since hospitals and pharmaceutical factories are sensitive environments that can be susceptible to the growth of microorganisms, floors must have anti-bacterial and anti-fungal properties to prevent the spread of infection and ensure continuous sterilization.

- Ease of cleaning and maintenance: Since floors in hospitals are subject to frequent cleaning operations, it is necessary that they have a smooth, non-porous surface, which facilitates cleaning and prevents the accumulation of dirt and pollutants.

- Resistance to chemicals: In pharmaceutical factories, floors are constantly exposed to strong chemicals, so it is necessary that they be made of materials that can withstand corrosion and maintain their quality over time.

- High endurance and hardness: Due to the constant movement of heavy equipment and medical vehicles inside hospitals and factories, the floors must be able to withstand high pressure without breaking. It corrodes Or easily damaged.

Choosing the right flooring in hospitals and pharmaceutical factories not only enhances hygiene and safety, but also contributes to improving work efficiency and ensuring an ideal environment for patients and workers alike.

Flooring for food factories

Epoxy is one of the basic and indispensable elements in concrete floors for factories due to its multiple uses and many benefits in industrial environments. It contributes greatly to enhancing the quality and safety of work, which makes it a vital component that cannot be ignored. Here is the importance of epoxy in factories:

- Enhancing the durability of structures: Epoxy improves the bond strength between materials, which enhances the solidity of floors and prevents their corrosion over time.

- Increased safety level: Without epoxy, structures become more susceptible to damage, which may pose risks to the safety of workers and equipment inside factories.

- Extending the life of products: It contributes to the production of strong products that can withstand corrosion and damage, which enhances their quality and supports their sustainability for long periods.

- Reducing maintenance and production costs: By improving the efficiency of industrial processes, epoxy helps reduce the need for frequent maintenance, which reduces costs.

- Creating a safer work environment: Epoxy provides an additional layer of protection that prevents accidents such as slips and corrosion resulting from exposure to chemicals.

- Environmentally friendly: It contributes to reducing industrial waste and reducing pollution, which makes it an ideal choice for many establishments.

Besides its use in concrete floors for factories, epoxy is also used in wall and ceiling coatings, enhancing the strength of construction and providing additional protection.

It is also an effective solution to protect against environmental risks, such as chemical spills and leaks, as it prevents the spread of damage and maintains the work environment safe and clean.

Read also about: Ucrete flooring

slip resistant floor tiles

Slip and fall accidents can lead to serious injuries and costly legal consequences, so choosing anti-slip flooring is an essential step to reduce these risks and ensure the safety of individuals, as these floors provide a stable and safe surface, which reduces the possibility of accidents.

The importance of slip resistant floor tiles increases in environments that are constantly exposed to moisture or dripping liquids, such as kitchens, bathrooms, and outdoor areas, as they enhance the strength of cohesion with the ground, which reduces the risks of falls and injuries, especially in places with intense use.

In addition, these floors provide additional protection, which gives a feeling of security and peace of mind in various spaces. Therefore, when choosing anti-slip floors, a group of factors that affect their effectiveness must be taken into account, such as the type of material and the extent of its resistance to slip, as follows:

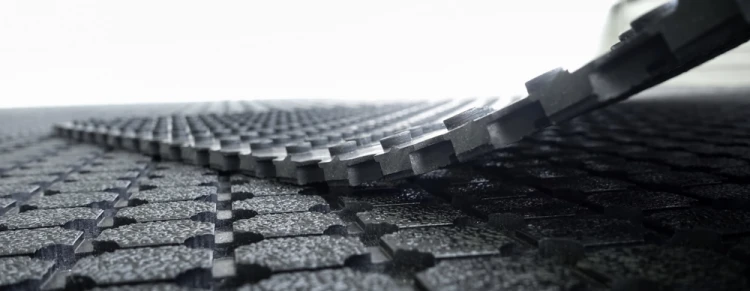

- Rubber flooring: It is characterized by its superior ability to resist slipping even in wet conditions thanks to its high coefficient of friction. It also provides comfort when walking and absorbs noise, making it an ideal choice for residential and commercial spaces.

- Vinyl flooring: It provides good resistance to slipping in addition to its high ability to resist water and stains. It is characterized by various designs that mimic natural materials such as wood and stone. It is also easy to maintain, but it may need refinishing over time.

- slip resistant porcelain tile flooring or ceramic tiles: They are a popular choice in kitchens, bathrooms, and outdoor areas, as they are available in different types that provide high adhesion to the foot. However, it is necessary to choose tiles specifically designed to resist slipping, taking into account the coefficient of friction to ensure the required level of safety.

- Epoxy flooring: Provides a durable surface that is resistant to chemicals, and its anti-slip properties can be enhanced by adding materials such as quartz or aluminum oxide. These are typically used in industrial environments but are also suitable for some residential and commercial applications.

These materials are among the most popular options for anti-slip flooring, and it is always recommended to compare them according to the specific needs of each space to ensure the perfect choice.

Refrigerator floors

Global cold and freezer room flooring is carried out by individuals without the need for specialized equipment, according to the following steps:

- Floor manufacturing: The floor is made of polyurethane with a density of 40 kg/cubic meter, which is injected between two layers: the first of galvanized sheet coated with electrostatic paint, and the second of polywood with a thickness of 13 mm.

- Adding a layer of protection: The polywood layer is covered with a layer of fiberglass with a thickness of 2-4 mm, which creates a non-smooth surface, allowing easy charging and discharging inside the room without fear of people slipping.

- Advantages of fiberglass: Fiberglass is characterized by its high hardness and resistance to scratches and damage, which gives the floor a longer lifespan.

- Surface reinforcement: A layer of aluminum plate can be added over the fiberglass layer for greater durability.

- Ease of cleaning: The fiberglass layer allows for easy cleaning of the floor using water and sterilizing liquids, without affecting its quality, since it is the same material used in making water tanks and insulating fishing boats.

- Edge treatment: A 10 cm sanding is carried out at the intersection of the walls and the floor, to prevent fluids from leaking between them, which enhances insulation and protection.

Industrial flooring company in Egypt

At OSISCO, we realize that each customer has special and diverse needs, so we provide a variety of flooring options that meet different requirements.

Whether you are looking for durable flooring that is resistant to chemicals and can withstand heavy materials without being affected, also if you are looking for a design that adds a touch of sophistication to your work space, whether in factories or hospitals, we offer the ideal solutions that suit your needs.

Read more about: Terrazzo tiles price in Egypt